Mine-Ready Driverless Transport Van with 380mm Wading Depth

Get Latest Price| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | ningbo,qingdao,shanghai |

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | ningbo,qingdao,shanghai |

Model No.: Model Z8 (2025) three flying wing version

Brand: Newbase

Place Of Origin: China

Cargo Box Volume: 8m³

Load Capacity: 1500kg

Maximum Range When Empty: 210km

Comprehensive Urban Range: 150km

Dimensions (mm): 4008*1648*2300

Minimum Ground Clearance (mm): 154

Maximum Wading Depth (mm): 380

Minimum Turning Radius (m): 5.4

Maximum Climbing Angle: 20%(11.3°)

Speed (km/h): 55

Operating Temperature (℃): -30~60

Waterproof Rating: IP55

Maximum Range (km) When Unloaded: 210/260

Urban Comprehensive Range (km): 150/190

Load Capacity (kg): 1500/1400

Body Color: Star Sea White / Glacier Blue

Lock Type: Automotive Grade Smart Electric Lock

Type Of Power Battery: Lithium Iron Phosphate

Battery Capacity (kWh): 34.8/46

Charging Time (h): Standard: 11.5h/15h Optional: 7h/9h/3h/4h

| Selling Units | : | Piece/Pieces |

| Package Type | : | Cartons and wooden boxes |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

| Design Highlights | Adaptation Value for North American Mining Areas |

|---|---|

| Streamlined Body + Three-Flying-Wing Cargo Box | The Newbase Z8 North America Mine Site Driverless Transport Vehicle:Body width matches mining zone road standards (fits narrow industrial passages). The three-flying-wing design (double-side + rear doors) enables forklifts to load/unload from any angle —The Newbase Z8 -30~60℃ Temperature-Resistant Mine Driverless Van: ideal for high-frequency hauling in mining industrial parks, cutting handling time by 50%. |

| "Aurora" Custom LED Headlights | Light coverage is 40% larger than traditional models. Adaptive brightness handles low-light conditions in mining tunnels or 24/7 shift operations. Enhances visibility and safety for round-the-clock transport. |

| Integrated Sensor Array | Equipped with 4 solid-state lidars + 13 cameras + millimeter-wave radars. Flush-mounted design avoids interference from mining dust, debris, and onsite equipment. IP55-rated sensors withstand extreme operating temperature range: -30℃ winter in Canadian mining regions and 60℃ summer heat in Arizona mines. |

| Modular Cargo Box Structure | • Column-Free Opening: Unobstructed access for rapid loading of mining materials/equipment. • Waterproof Rear Flying Wing: Sealing meets rainy-season demands (e.g., Appalachian mining areas’ rains), keeping electronics/packaged goods dry. • Expandable Flat-Top + 1500/1400kg High Payload: Cargo capacity lets you haul 25% more per trip than competitors, boosting efficiency by 30%. |

| Competitors’ Product Shortcomings | North American Mining Customers’ Core Pain Points | Newbase Z8 Series Robovan Competitive Edges |

|---|---|---|

| 1. Loading/Unloading: Manual handling; single process takes ≥20 minutes (low efficiency). 2. Environmental Adaptation: ≤200mm wading depth (rainy-season transport interruption); -10~40℃ operating temperature range (winter startup failure); IP54 protection (frequent dust faults). 3. Payload: Lower capacity limits single-haul efficiency. | 1. High manual loading cost + low efficiency = delayed production rhythm. 2. Rainy-season transport interruption (5–7 days/month, loss over $100k) + winter startup failure (extra $5,000/month for heating). 3. Frequent dust-related sensor failures (2–3 repairs/month, cost over $3,000). | 1. Efficiency: Forklift-direct loading/unloading (single process ≤5 minutes) + 1500/1400kg high payload → 25% more per trip, 30% efficiency boost, slashing manual handling costs. 2. Extreme Adaptation: 380mm wading depth + (-30~60℃) operating temperature range → all-weather 24/7 operation, no transport interruptions in rain or winter. 3. Durability: IP55 protection → dust failure rate reduced to below 2%, annual maintenance cost saved by $20,000. 4. Range: ≥150km range → meets 24/7 shift hauling needs in industrial mining scenarios. |

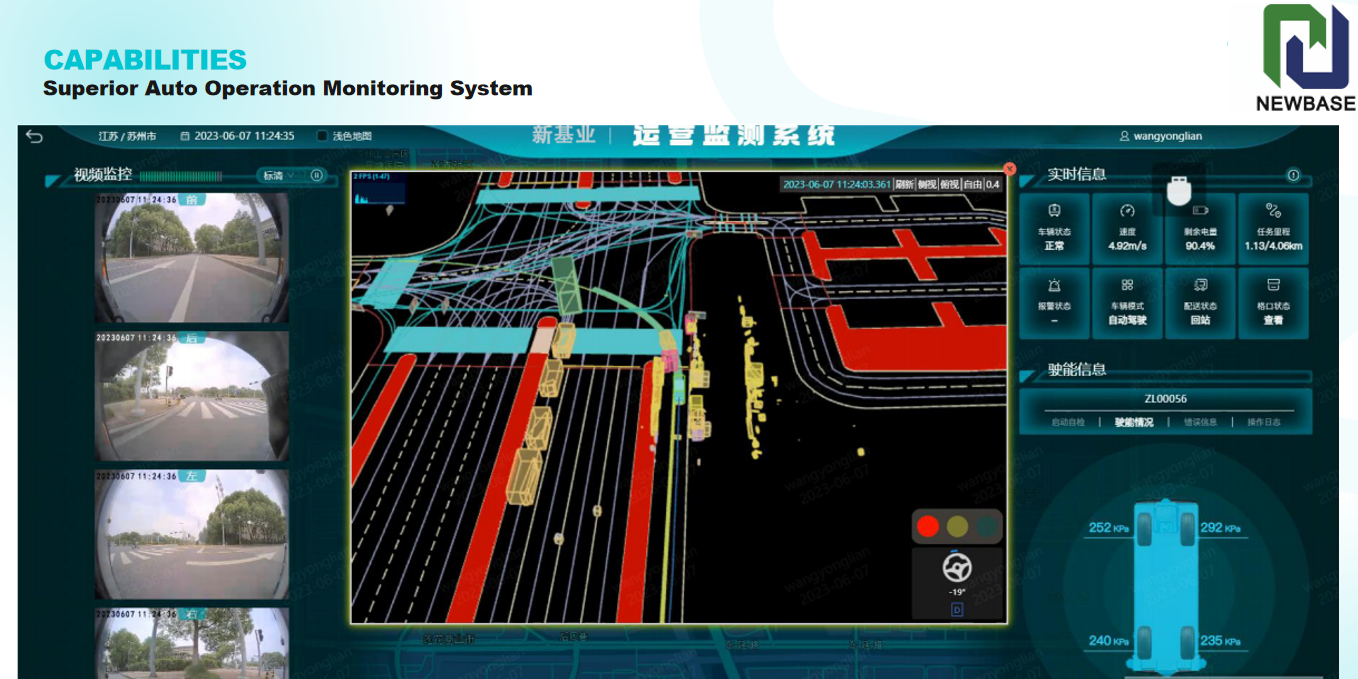

Coverage & Accuracy: 300m front/rear + 100m left/right detection range. The 99.3% dynamic obstacle recognition accuracy solves risks from mining equipment, mining trucks, and personnel in complex mining environments — a top pain point for mining logistics teams. It precisely identifies mining-specific targets: heavy machinery, transport carts, and temporary obstacles.

Core Tech: Industry-leading triple fusion (binocular 3D vision + lidar + millimeter-wave radar) for 360° obstacle detection. Our Mine-Ready Driverless Transport Van with 380mm Wading Depth for North America:handles 15+ complex mining scenarios (e.g., workers in safety gear, heavy-duty equipment, narrow industrial passages) simultaneously.

Decision response time: 35ms (4x faster than industry average). BEV bird’s-eye view (a top-down 3D map) + OCC occupancy network (for precise positioning) enables <5cm error in 3D mapping — critical for avoiding collisions in crowded mining industrial areas.

As a L4 Level Autonomous Driving Vichel, hardware modular design supports 24/7 operation in mining zones. Vehicle-grade solid-state lidar lifespan: 6+ years (vs. competitors’ 1–3 years) — reducing replacement frequency in dusty mining environments.

| Customer Type | Core North American Mining Market Needs | Newbase Autonomous Logistics Van Solution |

|---|---|---|

| Mining Companies (e.g., Rio Tinto, BHP North American branches) | High-frequency multi-stop material hauling (e.g., ore from extraction sites to processing plants). Cut labor and maintenance costs. Zero equipment collision accidents. | - 50% faster loading/unloading + 25% more per payload = 30% higher daily hauling efficiency. - IP55 protection + (-30~60℃) operating temperature range + 380mm wading depth = no rainy/winter transport interruptions, avoiding $100k+ monthly loss. - High-precision obstacle avoidance + durable sensors = dust failure rate <2%, saving $20k+ annually on maintenance, lowering collision accident rate to near 0. |

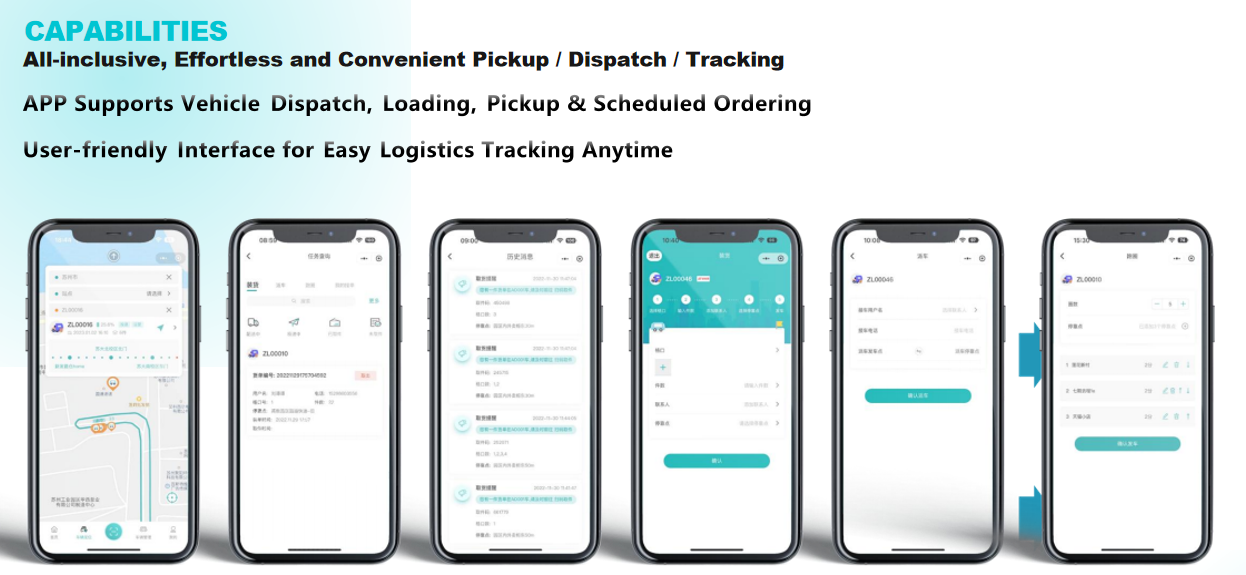

| Mining Third-Party Logistics (e.g., specialized mining transport providers) | Large-scale fleet operation in mining zones. Low failure rate under extreme mining conditions. Fast on-site support for breakdowns. | - 4% annual failure rate (vs. industry 12%) = less downtime, boosting mining site logistics efficiency by 15%. - Local service centers (e.g., Denver, Toronto): on-site support within 3 hours for mining zone breakdowns. - Fleet management platform: Optimizes routes (e.g., Arizona copper mine sites) and maintenance alerts for 100+ vehicles. |

| Service Type | Exclusive Guarantee |

|---|---|

| Warranty Service | 5-year free warranty on core components. |

| Door-to-Door Service | Free delivery to your mining site/warehouse. Includes on-site operator training for mining zone operations. |

| Insurance Protection | $10 million public liability insurance + $250,000 property insurance — covering risks in mining zone hauling. |

| Customization Service | • Cargo Box: Tailored to mining needs (e.g., reinforced structure for heavy ore, specialized compartments for equipment parts).It can also be used in conjunction with Newbase's refrigerated tricycles and Mini Refrigerated Van to provide an integrated logistics solution. • Branding: Body logos/custom paint matching mining company identities. • Connectivity: Complimentary 5G data cards (works with AT&T/Telus/T-Mobile) for remote mining zone fleet management. |

| After-Sales Rights | • Serious quality issues (e.g., failure to meet extreme environment specs) → full vehicle replacement. |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.