Customized IoT-Enabled Mobile Refrigerated Container for Pharmaceutical

Get Latest Price| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | qingdao,ningbo,shanghai |

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | qingdao,ningbo,shanghai |

Brand: Newbase

Operating Temperature Range: -20℃ ~ +35℃

Refrigerating Capacity: R404a

Compressor Type: DC inverter

Power Supply Voltage: DC 53V ~ DC 72V

Battery Capacity: 6400Wh

Maximum Operating Current: < 30A

Endurance Time At -18℃: 24h (under the condition of ambient temperature 30℃)

Condenser Type: Air-cooled finned type

Evaporator Type: Finned type

Set Minimum Temperature: -20℃

Set Temperature Difference: ±1℃

Protection Class: IP54 (main components)

Noise Level: ≤ 70dB(A)

Cabinet Color: Blue (shell)

| Selling Units | : | Piece/Pieces |

| Package Type | : | Cartons and wooden boxes |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

±1℃ Precise Temperature Control | IoT Remote Monitoring | GSP Compliance | 72H Power-Off Battery Life

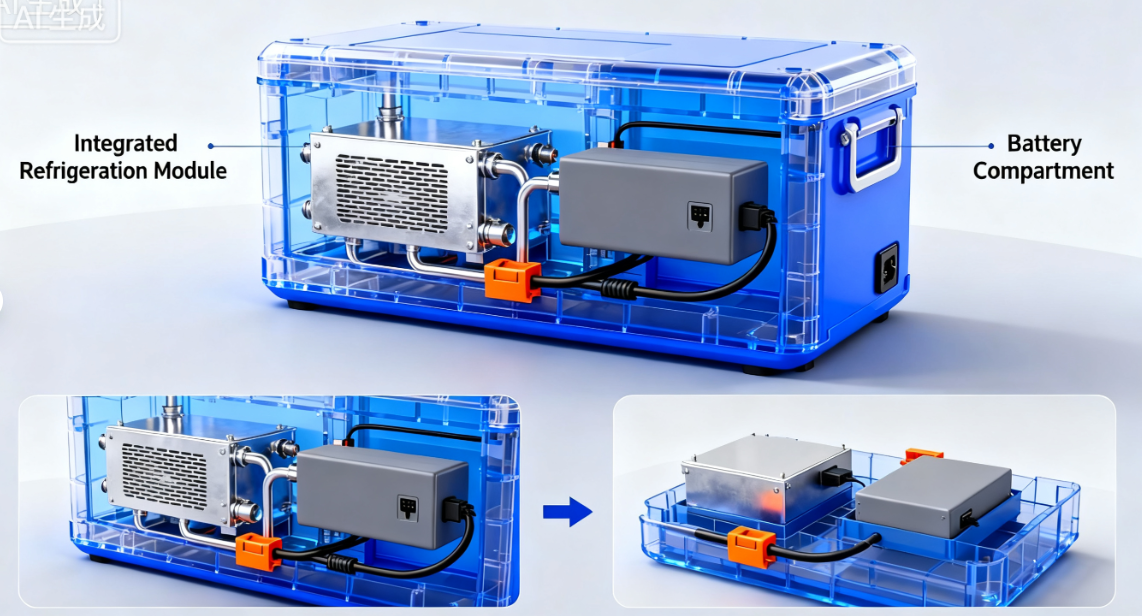

For B2B cold chain logistics partners in pharmaceuticals and healthcare, cargo loss caused by power outages, temperature fluctuations, or rigid vehicle constraints has long been a costly pain point. Newbase’s IoT-Enabled Mobile Refrigerated Container for Pharmaceutical and Emergency Cold Storage is engineered to address these challenges comprehensively, while complementing our core product lineup including Cold Chain Refrigeration Container, Refrigerated Tricycle, and Transportation Refrigeration Units.

This Pharmaceutical Cold Chain Container requires no vehicle modification, seamlessly fitting tricycles, vans, and light trucks alike. With a temperature control range of -20℃ to +35℃ (±1℃ accuracy) and IP67 protection rating, it safeguards critical cargo such as vaccines, blood products, and biologics—even in harsh road conditions. Equipped with IoT remote monitoring technology, it eliminates "broken chain" risks, while its GSP compliant cold chain container design automates regulatory documentation, saving hours of audit preparation.

Whether for last-mile vaccine delivery, cross-border pharmaceutical shipping, or emergency relief operations, this Mobile Emergency Cold Storage Container ensures uncompromised cargo safety. Its modular design also supports easy integration with Newbase’s Mini Refrigerated Van, creating a end-to-end cold chain solution for diverse logistics needs.

| Industry Pain Points | Our Solution | Created Value |

|---|---|---|

| Temperature control fluctuation & high cargo damage rate | Dual inverter refrigeration system (±1℃ accuracy) | Pharmaceutical transportation pass rate increased to 99.8% |

| Equipment vulnerability in extreme road conditions | Military-grade seismic design + IP67 protection rating | 76% reduction in equipment failure rate |

| Multi-batch shipping management confusion | Intelligent cloud management system + electronic fence | 40% increase in transportation scheduling efficiency |

| Sudden power failure leading to liability disputes | 72-hour backup battery life | 90% reduction in insurance claims |

| Time-consuming compliance documentation | Auto-generated GSP standard temperature control reports | 85% reduction in audit preparation time |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.