Customized IP67 Mobile Refrigerated Container for Emergency Relief Use

Get Latest Price| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | ningbo,qingdao,shanghai |

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Land,Air |

| Port: | ningbo,qingdao,shanghai |

Brand: Newbase

Operating Temperature Range: -20℃ ~ +35℃

Refrigerating Capacity: R404a

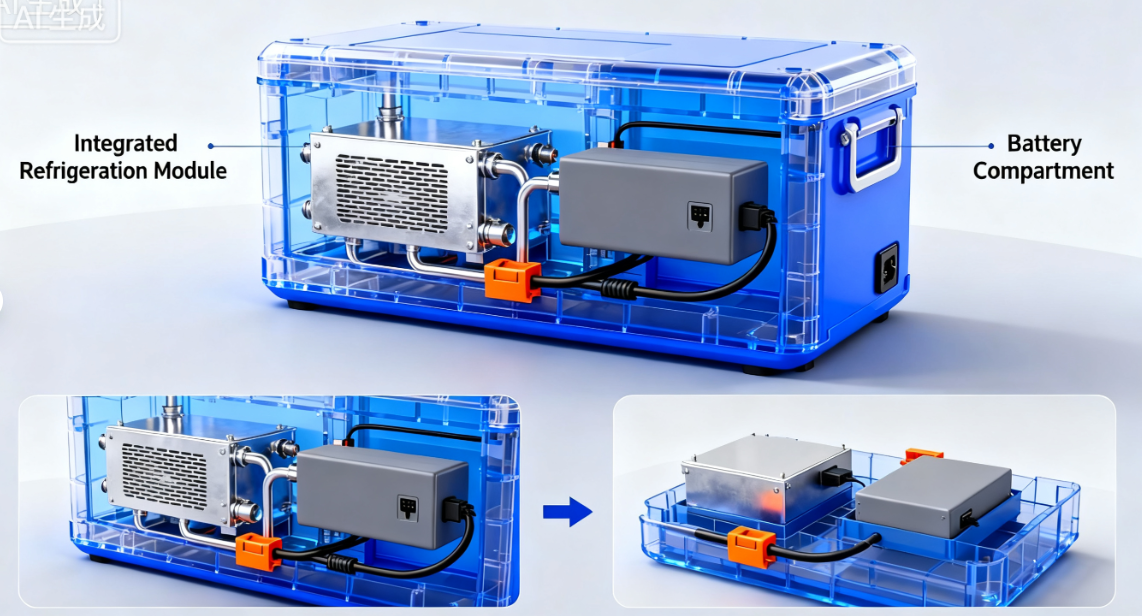

Compressor Type: DC fixed frequency

Power Supply Voltage: DC 53V ~ DC 72V

Battery Capacity: 3200Wh

Maximum Operating Current: < 30A

Endurance Time At -18℃: 12h (under the condition of ambient temperature 30℃)

Condenser Type: Air-cooled finned type

Evaporator Type: Finned type

Set Minimum Temperature: -20℃

Set Temperature Difference: ±3℃

Protection Class: IP54 (main components)

Noise Level: ≤ 80dB(A)

Cabinet Color: Off-white (shell)

| Selling Units | : | Piece/Pieces |

| Package Type | : | Cartons and wooden boxes |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Reefer Container for Cold Chain Logistics | Seafood Deep Freeze Container (-18℃) | Battery-Powered Mobile Cold Storage

Still troubled by cold chain cargo losses caused by power outages or vehicle restrictions? This Newbase IP67 Mobile Refrigerated Container for Emergency Relief Use is built for B2B logistics needs! No modification required, suitable for trucks, tricycles or vans; -20℃ to +35℃ temperature control ensures the safety of pharmaceuticals/fresh goods; IoT remote monitoring prevents waste; IP54 protection rating handles harsh road conditions. Whether it's last-mile delivery, cross-border transportation or emergency rescue, it meets your needs! As a key part of our cold chain solutions, it complements our Refrigerated Tricycle and Mini Refrigerated Van to form a complete logistics network. Want to reduce cold chain risks with reliable Reefer Container for Cold Chain Logistics? Contact us anytime!

Due to the poor temperature control performance of traditional cold chain turnover containers, food is prone to spoilage during transportation, resulting in massive food waste. According to statistics, the annual food loss in China caused by inadequate cold chain logistics reaches as high as 12 million tons, with a value of approximately 100 billion yuan.

Food spoilage not only causes economic losses but also may trigger food safety incidents, endanger consumers’ health, and bring severe reputation crises to enterprises.

| Industry Pain Points | Our Response | Created Value |

|---|---|---|

| Temperature control fluctuation and high cargo damage rate | Dual inverter refrigeration system (± 1°C accuracy) | The pass rate of pharmaceutical transportation increased to 99.8% |

| Equipment is vulnerable to damage in extreme road conditions | Military seismic design + IP67 protection rating | 76% reduction in equipment failure rate |

| Multi-batch shipping Management mix | Intelligent cloud management system + electronic fence | 40% increase in transportation scheduling efficiency |

| Sudden power failure leads to liability disputes | 72 hours of battery life (ideal for Battery-Powered Mobile Cold Storage) | Reduce insurance claims by 90% |

| Compliance documentation is time-consuming | Automatically generate GSP standard temperature control reports | 85% reduction in audit preparation time |

The IP67 Mobile Refrigerated Container for Emergency Relief Use uses durable HDPE material, with a service life far longer than traditional plastic/foam. This reduces product replacement frequency and waste generation, aligning with global sustainability goals. When paired with our Mini Refrigerated Van, it further cuts carbon emissions by optimizing energy use during transportation.

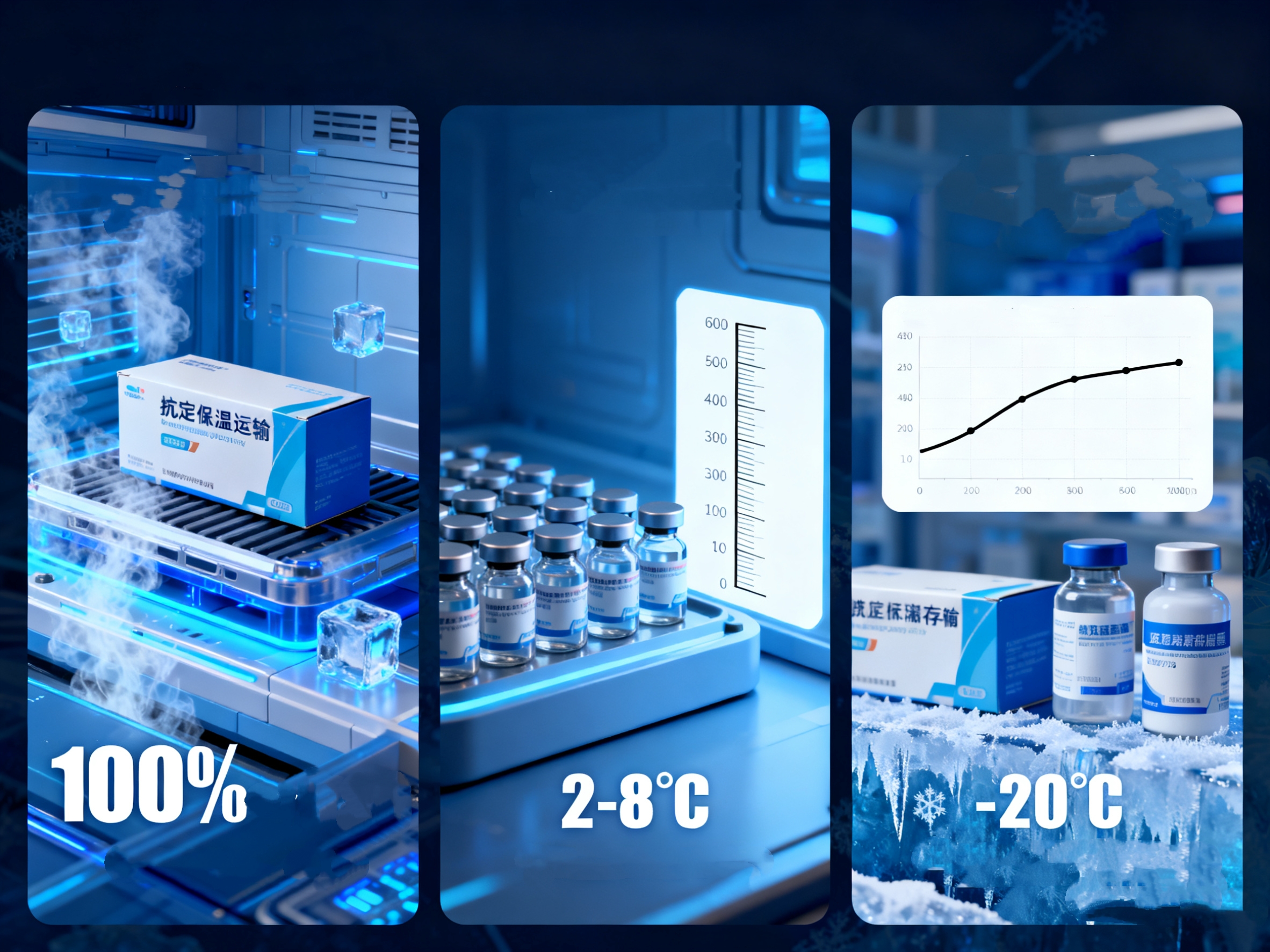

Ideal as a Seafood Deep Freeze Container (-18℃), it reduces perishable food loss by over 30% during long-distance transport. Ensures 99%+ qualified rate for frozen food nationwide and supports e-commerce fresh delivery to remote areas.

Meets strict cold chain requirements for pharmaceuticals with stable temperature control. Ensures 100% qualification rate for antibiotics and maintains precise 2-8°C temperatures for long-distance vaccine transportation.

Supports cross-border e-commerce cold chain needs across different regions. Improves logistics efficiency and quality while integrating with warehouse management systems for end-to-end temperature control.

Adapts to diverse cold chain requirements for chemicals, laboratory materials, and reagents, ensuring their quality and performance during transportation in controlled temperature environments.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.