The Ultimate Guide to Cold Chain Temperature for Vaccines: From Polio to Pfizer

Introduction: Protecting Lifelines at the Critical Temperature

Vaccines are the bedrock of global public health, yet their life-saving efficacy hinges entirely on maintaining a strict temperature range. From the manufacturing facility to the patient's arm, every step constitutes the vital Vaccine cold chain.

Temperature excursions—even brief ones—can lead to reduced potency or total loss of vaccine viability. Therefore, Maintaining the cold chain is not just a logistical challenge; it is a commitment to public health safety and commercial integrity.

This guide will delve into the specific cold chain temperature requirements for different vaccines and demonstrate how modern

cold chain refrigeration containers secure this lifeline against disruption.

Understanding the Cold Chain of Immunization

The Cold chain of immunization encompasses the equipment, procedures, and personnel training necessary to ensure vaccines are stored, handled, and transported within the recommended temperature range.

Why Temperature Consistency Matters

For most biologics, exposure outside the acceptable threshold—either too hot or too cold—triggers molecular degradation. Our product’s emphasis on High-Efficiency Insulation and Refrigeration Systems is designed to mitigate these environmental risks:

1. Polyurethane Insulation Layer: The cabinet features a 5CM thick polyurethane foam layer, offering excellent thermal insulation properties. This effectively prevents heat transfer and loss, keeping the internal temperature stable.

2. Ice Pack Design: Equipped with high-efficiency ice packs made of special phase change material, the system rapidly cools and continuously releases cold energy during transport, ensuring contents remain protected even in the event of a power outage, thus enhancing reliability and safety.

3. High-Density Polyethylene Materials (HDPE): The construction utilizes HDPE+PE composite materials, known for corrosion resistance, compressive strength, and low-temperature durability, which collectively reinforce insulation for stable transport.

Critical Temperature Ranges: From Standard to Ultra Cold

Vaccine temperature requirements are not uniform. They are categorized into different cold chain storage temperatures based on their composition.

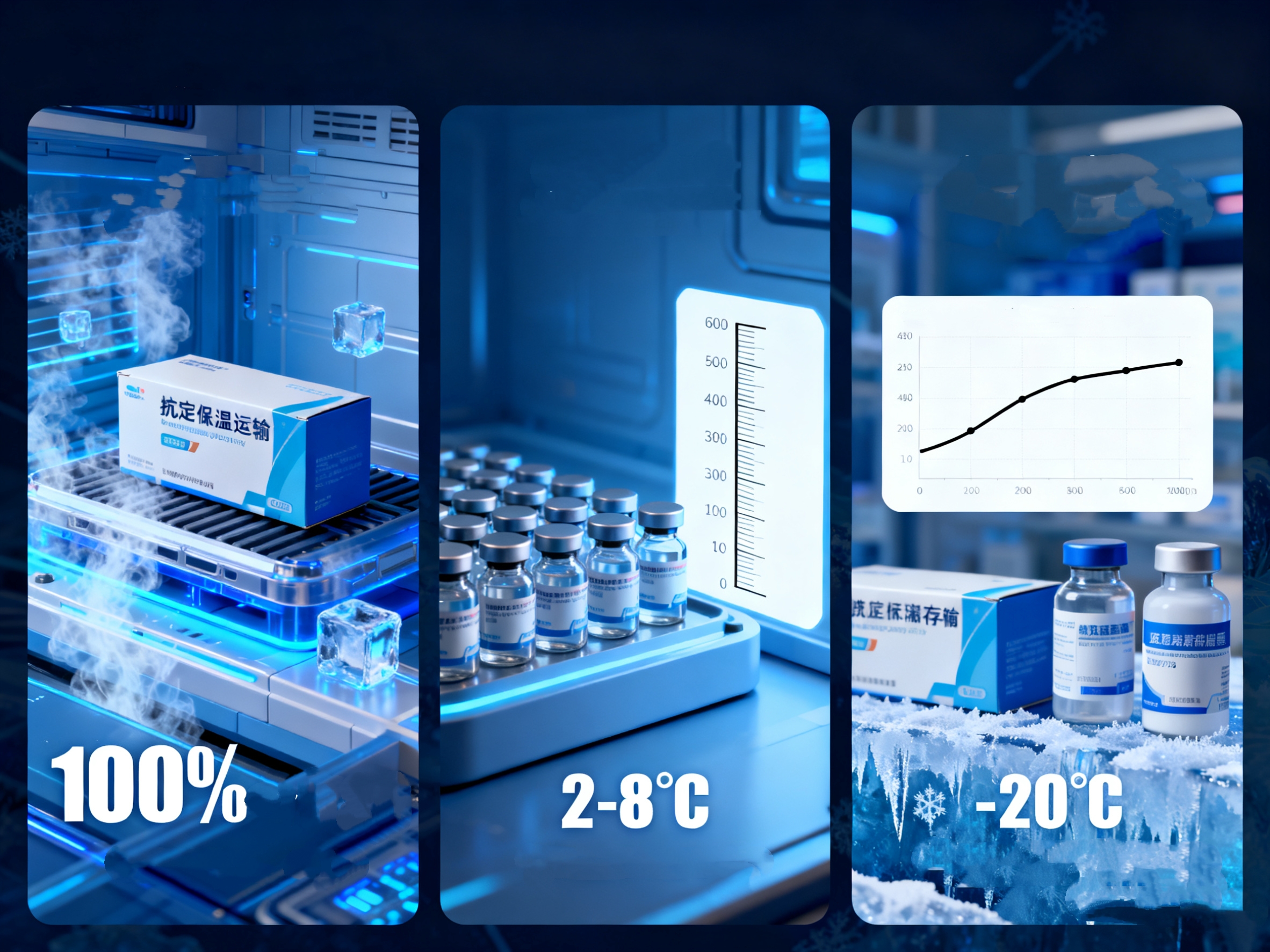

The +2°C to +8°C Standard (Standard Refrigeration)

This is the most common cold chain vaccine storage temperature range, applicable to most traditional vaccines (DTP, HepB, etc.).

1. Challenge: Must strictly avoid freezing, as sub-zero temperatures can destroy the protein structure of many vaccines.

2. Solution: Our products feature Refrigeration and Cold Storage Functions that rapidly reduce internal temperature while maintaining a stable, low-temperature environment. The cold storage function ensures the maintenance of low temperatures even when power is interrupted.

The -15°C to -25°C Range (Freezing Range)

Certain vaccines, such as the Oral Polio Vaccine (OPV), require storage and transport at sub-zero temperatures.

Key Placement: Meeting the stringent demands of the Polio vaccine cold chain relies on dependable, integrated refrigeration units.

Ultra Cold Chain for mRNA Vaccines

(Ultra-Low Temperature)mRNA vaccines, exemplified by the cold chain Pfizer requirements, demand extreme temperatures, often ranging from -60℃ to -80℃.

Key Placement: Ultra cold chain stability is achieved through our Integrated Refrigeration Unit. It contains an efficient compressor and evaporator, utilizing advanced refrigeration technology to quickly reduce internal temperature and maintain stable, low-temperature conditions.

Choosing the Right Equipment: Boxes vs. Containers

In developing effective cold chain logistics solutions, selecting the appropriate equipment is paramount.

Portable Solutions for Last Mile

Vaccine carrier boxes and small vaccine carriers are ideal for short-haul distribution in areas like cold chain in community health nursing settings, relying on ice packs and insulation to maintain temperature.

For long-haul, cross-regional cold chain transportation or the bulk storage of high-value biologics, your

Cold Chain Refrigeration Container offers significant advantages:

1. Active Temperature Control & Remote Management:

Real-time Temperature Monitoring: The product features a high-precision sensor to monitor and clearly display the internal temperature and humidity, allowing users to understand the cargo status and take timely action.

Remote Control and Alarms: Users can remotely monitor and manage the product via a mobile app or computer. If the temperature exceeds the set range, the system automatically alerts users, preventing loss.

2. Flexible Transport Adaptability:

No Vehicle Modification Required: The product features flexible adaptation designs like roller wheel design and splicing groove design. It easily fits various transport tools without vehicle modification, lowering operational costs and time.

Splicing Groove Design: Allows the container to be conveniently secured to various transport vehicles (trucks, vans, etc.), enhancing adaptability and reducing logistics costs.

Modular Design: Integrated modules and battery packs are modular, allowing for flexible replacement and upgrades based on demand, reducing maintenance costs and extending product lifespan.

3. High Reliability and Capacity:

Multiple Sizes and Capacities: The product offers various sizes and capacity specifications to meet diverse customer needs, enhancing versatility and market reach.

Detachable and Separable Design: The integrated refrigeration unit is designed to be detachable from the main cabinet for easy cleaning and maintenance, improving flexibility and maintainability.

Monitoring and Maintaining the Chain

The key to successful cold chain maintenance lies in continuous temperature monitoring cold chain and rapid intervention.

1. Real-time Monitoring: The intelligent system provides real-time monitoring and regulation of the internal environment, allowing users to understand the cargo status and take timely measures, thereby enhancing transport safety and reliability.

2. Automatic Adjustment Function: The product can automatically adjust temperature and humidity based on changes in the internal environment without manual intervention, ensuring the cargo remains in optimal transport conditions.

3. Anti-fog Lighting and Camera: Equipped with anti-fog lights to prevent moisture buildup and a camera for round-the-clock surveillance, ensuring the security and traceability of the transportation process.

4. Environmental and Energy Advantages:

Our product incorporates Energy-Saving Design and Eco-friendly Materials:

Energy-Saving Design: The low-energy, high-efficiency cooling design reduces energy consumption and aligns with current environmental policies.

Eco-friendly Materials: The use of high-density polyethylene and other sustainable materials ensures recyclability and supports green, sustainable logistics development.

Conclusion

Whether navigating the standard temperature requirements for immunization and cold chain or tackling the extreme demands of the ultra cold chain, selecting the right temperature-controlled equipment is vital for securing the efficacy and safety of sensitive cargo.

Our Cold Chain Refrigeration Container provides a highly reliable, efficient, and cost-effective solution through its multi-functional integration, smart monitoring, superior insulation, and flexible adaptability.

Looking for high-performance Cold Chain Refrigeration Containers for your pharmaceutical logistics? Contact us today for a personalized quote and technical consultation to secure your temperature-sensitive cargo.

Mobile Phone :+86 15890051653

Email :melissa@newbasen.com

Website :https://www.newbasecool.com